Table of Contents Show

Distribution Transformer load balancing is a critical activity which can reduce transformer load losses and keep the supply network healthy. This means lower AT&C loss for DISCOMs and more reliable power supply for customers. Sounds like a win-win, doesn’t it? So why don’t DISCOMs dedicate more time and resources to DT load balancing?

Difficulties in conducting load balancing of DTs

The answer lies in the difficulties of conducting on-ground load balancing. Let’s picture this with an example –

Suppose you have a 250 kVA distribution transformer with the phase currents given below. Let’s assume these values persist for a long time period. This way, we wouldn’t have to delve into load duration curves and associated complexities.

Typical phase currents of a 250 kVA DT:

IR = 300 Amps, IY = 200 Amps, and IB = 190 Amps

Clearly, the red phase is loaded more than yellow and blue phases. Therefore, it is easy to prescribe a remedial action – “Reduce 70 Amps worth of load from the red phase and connect 30 Amps to yellow and connect the remaining 40 Amps to blue phase.”

Simple, isn’t it? Not quite.

You see, in most cases, site engineers struggle with with lack of information. “Which consumers to shift from one phase to the other to achieve a balanced scenario?”

Incorrect tagging of consumers

Customer connections are not accurately tagged to their respective power source in most DISCOMs. For instance, a customer might be receiving electricity from X distribution transformer but could be incorrectly tagged to Y. Even feeder-wise tagging of consumers is absent / incorrect in many cases, leave alone DT-wise tagging.

Consumer indexing and GIS integration during R-APDRP scheme did provide some level of sanctity. However, there were no systematic efforts to update GIS data post R-APDRP. Meanwhile, accuracy level of consumer tagging plummeted as a result of all-prevailing entropy. The resulting chaos left site engineers caught in a spaghetti of wires.

Solution – Automatic consumer tagging

I propose here, a system of automatically tagging consumers to the feeder, its corresponding DT – even to the relevant phase of the DT. The proposed system has the potential to auto-update even during change of source – say while back-feeding the system from a ring-main unit.

Here is how the system will work –

Smart meter data with ML analytics

Making the data set

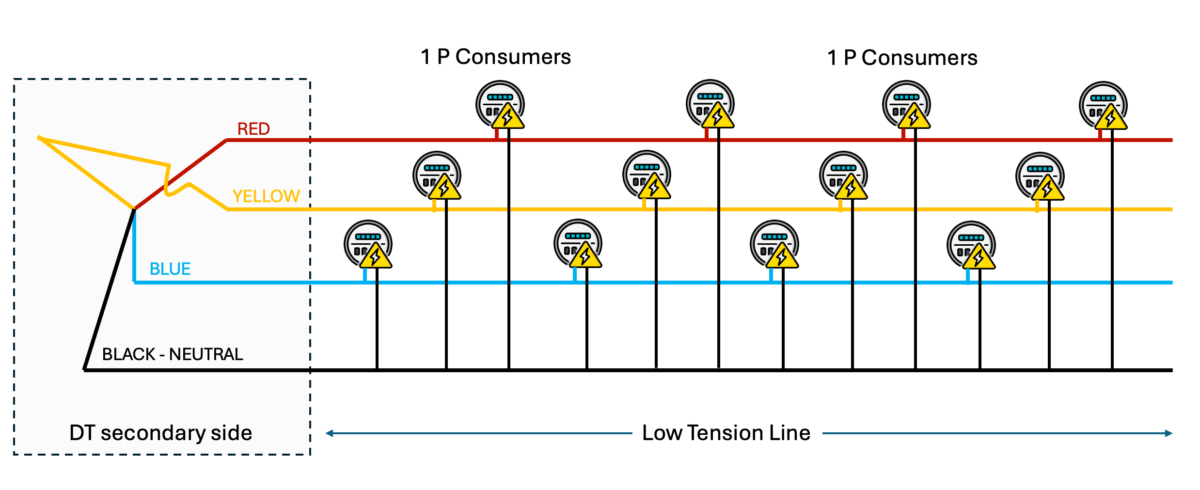

Smart DT meters and Smart consumer meters are capable of providing the voltage profile of DT and consumers respectively at a constant intervals (say 15 minutes or 96 times in a day). This information typically resides as time series data in the Meter Data Management System (MDMS) software.

Therefore, it is possible to compare the voltage measured by the consumer meter and phase voltages of the DT. We can extend this to 96 daily comparisons per consumer per phase. So, we shall have a data set of 3 columns (one for each phase) with 96 daily data points for each customer. Lets call this data set ‘phase comparison’ for simplicity.

Handling of errors and LT line loss

Of course, there would be inherent errors in calculation of voltage both by the DT meter as well as the consumer meter. This is due to the accuracy class of meters. But these errors would be present in the same proportion in each phase comparison. Thus, a properly designed ML algorithm can learn this proportion and cancel it out.

Further, there would also be a voltage drop associated with the length of LT line between the DT and each connected consumer. The length of line and the conductor material is constant for each customer. Therefore, this voltage drop shall be in same proportion for a given customer in its phase comparison. Again, the ML algorithm should be able to cancel out this as well.

ML Classifier for customer tagging

Now, all that remains is a typical ML-based classification problem. The algorithm has to look for consistencies in phase comparison and classify consistent patterns in the relevant phase under the appropriate DT and feeder. For lower quantity of data, the tagging may be faulty, no doubt. As the system gets intelligent with more data points on the time series, accuracy levels will increase.

DT load balancing with the ML solution

Once correct tagging is achieved, the system can be modified to find out the degree of unbalance in a set of DTs. Armed with the knowledge of phase-wise currents and instantaneous customer loads, the system can now give actionable insights to maintenance crews. An example of balancing action point can look like this –

“Disconnect consumer numbers K113, K115 and K117 from R phase. Connect K113 to B phase. Connect K115 and K117 to Y phase.”

Such kind of action points are easy to execute and the results of the action can be realized better through intelligent tracking by the software itself.

Other benefits of this solution

Accuracy in Energy Accounting

Most DISCOMs are unable to conduct DT-wise and Feeder-wise energy accounting due to incorrect tagging of customers. Even when energy accounting is mandated by Power Ministry, DISCOMs are unable to comply. At most, their efforts result in absurd value of losses. With more accurate customer tagging, this can get resolved by the proposed ML based solution.

Correct outage information to consumers

Incorrect consumer tagging affects Outage Information data too. For instance, you may get an outage notice for maintenance work on some other transformer / feeder. Worse still, you may even end up not getting an outage notice for maintenance work on your DT leaving you irate and annoyed. This too can get resolved by the proposed ML based solution.

Faster restoration time during outage

Individual consumer level outage is always burdened with an element of delayed restoration due to incorrect tagging. Technicians always have to spend time in finding out which feeder / DT and phase is the source. This is especially cumbersome in urban India. with the proposed solution, technicians can breathe easy and concentrate on fault removal rather than source idenfication.

Conclusion

Accurate tagging of consumers with an ML based classifier can not only aid in DT load balancing but will also result in better and more accurate energy accounting. Proper load balancing will reduce load losses of DTs. Both of these will help in reduction of AT&C losses. Faster restoration and better information to customers will help DISCOMs to enhance the customer experience. In all respects, the solution is a win-win.

Do let me know in the comments if this is implemented in any area or already being implemented somewhere. Even otherwise, let me know your thoughts on this. It will make me very happy 🙂

Load balancing is very important for the life of assets , maintaining voltage profiles, and reducing technical losses. But it is often neglected.

The simple method suggested by Gaurav can help DISCOMs.